Tensile membrane structures offer an aesthetic, practical, and cost-effective way to provide roofing to either new or existing areas. These shade supporting structures have been put into use for the most part of the twentieth century and have found wide spread applications including, sports facilities, convention centres, concert halls, shade roofs of large commercial buildings, airport roofs, gas stations and terminals, to mention only a few. The membrane part in the structure is pre-stressed and thus enables the structure to maintain its form.

Two types of shapes are found in tension membrane structures. The first type is the ‘anticlastic structures’ with two double curvatures in the opposite direction while the second is a ‘synclastic structures’ with the double curvatures in the same direction. Anticlastic structures can take a variety of shapes and forms including, the arched vault, hyper and cone. Technically speaking a tension membrane structure is a combination of elements, which carry only tension and no compression or bending. This is the reason why the use of compression rings or beams, that form the bending or compression elements, is used in most tensile structures.

Why Tensile Membrane Structures?

The semi-translucent nature of fabric structures is what makes them a favourite with engineers and architects looking for roofing systems to cover large areas, such as sports stadia or terminals. Fabric structures help in increasing the sustainability quotient of a building in more ways than one. The fabric allows for entry of natural light, while cutting down the transmission of heat. The high reflectivity of the membrane makes it an ideal alternative to glass as a roof glazing system.

Tension membrane structures are usually reinforced using either PVC /Polyester or PTFE based coatings. This makes the fabric structure perform well from the fire performance perspective too. For example, a tension membrane structure with PTFE coating is rated non-combustible as per ASTM 136, making them completely safe. Additionally the inert nature of the fabric aids in self-cleaning, a characteristic which makes them perfectly suited for application over large areas.

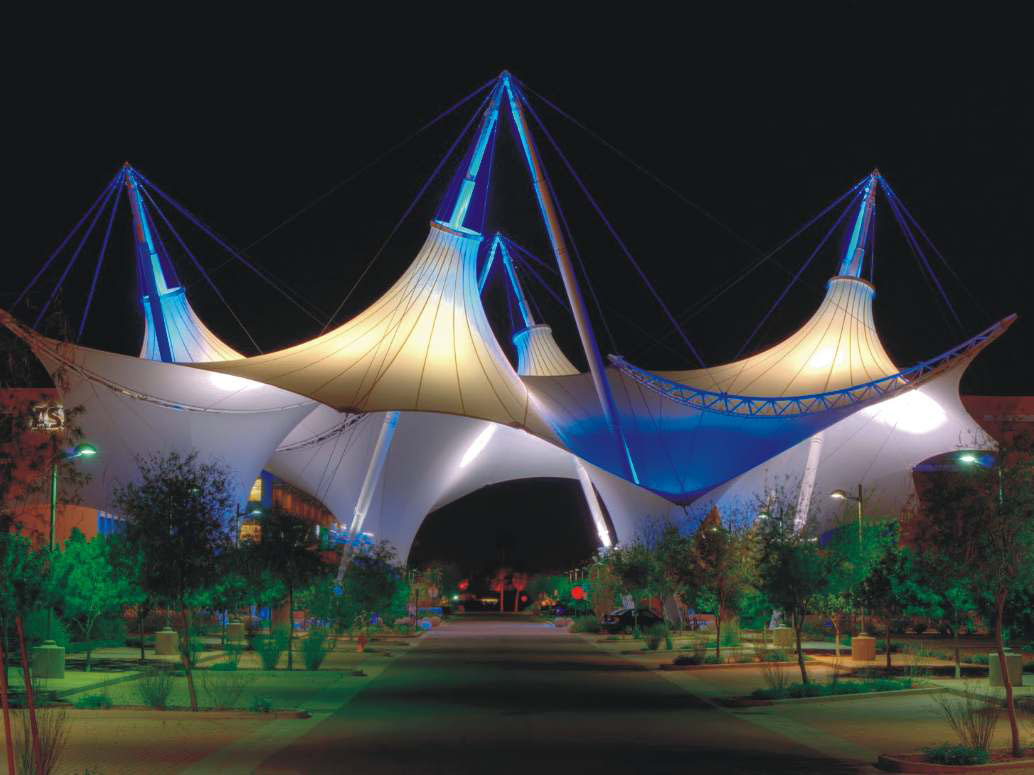

The dependency on artificial lighting is vastly reduced. The unique properties of light reflectance and transmission also offer exciting possibilities for lighting after dark. Directing lights under the canopy to reflect off the underside is a great way to use up lighters, but more even lighting can be achieved under the fabric by shining lights down on the fabric from above.

The thermal insulation achieved with a single layer of either PVC/Polyester or PTFE membrane with a typical weight of around 1200gm per sq metre and a U value of approximately 4.5 W/m2K, is more or less similar to that of glass. White is mostly the preferred colour when it comes to tension membrane structures. This is because with dark coloured membranes, the absorption of heat is very high. Dark coloured membranes can also re-radiate heat. White is therefore, the preferred choice in the case of tension membrane fabrics.

Roofing and Cladding

With tension membrane structures, it is possible to have both the roofing and cladding in one single structural element. Typically the seam and curve of the fabric structure that reflects the tension is aesthetically pleasing, while also being important for the structural integrity. Due to the integration of the roofing and cladding, the structures are also easy to clean and maintain, when compared to glaze glass roofing.

The roof, in the case of tensile membrane structures are factory welded and therefore easy to install, apart from acting as a weatherproof skin that does not contain expansion joints. All these factors enable rapid construction and coverage of large areas.

Span Capabilities

An excellent span capability is another factor that puts fabric ahead of other materials. While every other possible roofing material requires rigid intermediate support, it is not the case with fabric structures. The fabric can span from one boundary to another in one unbroken (sweep). This ensures that there are no sealing related issues that need to be addressed.

The amazing tensile capacity of fabric helps to reduce the number of components that make up the supporting framework to a minimum, thus enabling a structure that is much more light-weighted when compared to other types of construction. On the flip side though, the structures incorporating the concept need large foundations in order to prevent wind currents lifting the canopy. This factor is offset by the fact that in terms of cost foundations are cheaper to prepare, than the visible above ground construction components that are exposed to the vagaries of weather and therefore, more prone to damage. tensile membrane structures pdf Download